Coal Handling System

Coal Handling System Specification

- Accessories

- Conveyor Belt, Hopper, Dust Suppression System, Magnetic Separators

- Frequency

- 50 Hz

- Speed

- Control Variable

- Usage & Applications

- Coal Handling in Thermal Power Plants, Cement Plants, Steel Plants

- Model No

- CHS-1500

- Temperature Range

- -10C to 60C

- Efficiency (%)

- Above 95%

- Production Capacity

- Customizable

- Motor Power

- Up to 75 kW

- Driven Type

- Electric Motor

- Installation Guideline

- On-site Supervision Provided

- Automation Grade

- Automatic

- Type

- Coal Handling System

- Material

- Mild Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Based

- Drive Type

- Electric

- Voltage

- 415 V

- Power

- 75 kW

- Weight (kg)

- Approx. 18,000 kg

- Dimension (L*W*H)

- Customized as per project

- Color

- Industrial Grey

- Capacity

- Up to 1500 TPH

- Features

- Robust Construction, High Throughput, Low Maintenance

- Machine Type

- Material Handling Equipment

- Surface Finish

- Powder Coated

- Power Consumption

- Depends on System Size

- Service Support

- Available

- Safety Provisions

- Emergency stop, safety guards

- System Configuration

- Modular

- Dust Suppression System

- Available

- Operating Noise Level

- Below 70 dB

- Maintenance Access

- Catwalks with railings

- Belt Material

- Rubber/ PVC

- Conveyor Width

- 600-2000 mm

Coal Handling System Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Week

- Delivery Time

- 1 Week

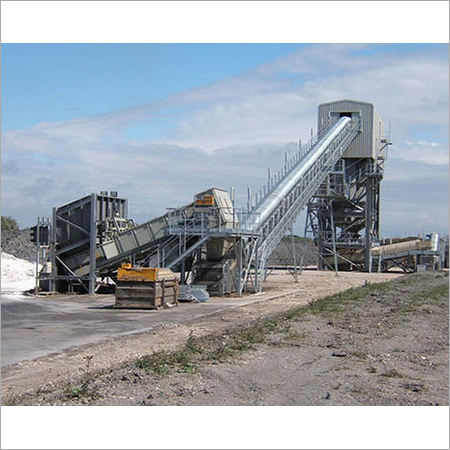

About Coal Handling System

we are Designing,manufacturing, & Export of Coal Handling System

We are the foremost company for providing Coal Handling System to the clients. Offered range can be customized as per our precious clients requirements. This product is widely appreciated by our clients who are situated all round the nation. Coal Handling System is stringently tested on certain parameters to eradicate all kind of defect before delivering at clients' end. This product is precisely manufactured in line with set industry norms by utilizing excellent grade components with the help of innovative techniques at professionals well-developed production unit

Additional Information:

- Item Code: CHS-1

- Port of Dispatch: KANDLA, MUNDRA,ETC

- Production Capacity: 1-100 TONS

- Delivery Time: 2-3 WEEKS

- Packaging Details: As Per Standard

Highly Efficient, Automated Coal Handling

The CHS-1500 utilizes advanced PLC automation and electric drives to achieve efficiency above 95%. Operators can customize production capacity and system configuration to match specific project needs, while variable speed controls allow precise throughput adjustment. This ensures consistent and reliable coal handling across different industries, maximizing operational uptime.

Comprehensive Safety and User-Friendly Maintenance

Safety is integral, with emergency stops, safety guards, and catwalks with railings, allowing quick and secure maintenance access. The modular system is equipped with a dust suppression system to enhance workplace safety and minimize environmental impact, while robust construction ensures stable performance even in demanding environments.

FAQs of Coal Handling System:

Q: How does the coal handling system ensure safety during operation?

A: The system is designed with multiple safety features including emergency stop switches, safety guards along the conveyor, railings on maintenance catwalks, and dust suppression systems. These measures collectively protect workers from potential hazards and promote a secure working environment.Q: What maintenance processes are involved with the CHS-1500 system?

A: Routine maintenance is streamlined through catwalks with railings that provide easy access to key system areas. Regular inspections include conveyor belts, drive systems, and dust suppression units to uphold optimal performance and extend equipment life. On-site supervision during installation ensures proper setup, minimizing future maintenance issues.Q: When should the conveyor belts be selected as rubber or PVC?

A: Rubber belts are typically chosen for heavy-duty, high-wear environments such as coal handling in large-scale thermal power plants. PVC belts are suitable for lighter applications or where chemical resistance is needed. Selection depends on the projects specific load, operating conditions, and required durability.Q: Where can this coal handling system be implemented?

A: This system is ideal for coal movement and management in thermal power plants, cement plants, and steel factories. Its modular design and customizable dimensions allow it to fit into varied industrial layouts in India and similar export markets.Q: What benefits does the dust suppression system provide?

A: The integrated dust suppression system minimizes airborne particulate emissions, thereby improving air quality and workplace safety. This feature also helps in regulatory compliance and reduces the cleaning burden on facility maintenance teams.Q: How does the PLC-based control system enhance operation?

A: The PLC control system automates and monitors the entire coal handling process, allowing for real-time adjustments and diagnostics. This increases operational efficiency, reduces manual intervention and risk of error, while also enabling seamless integration with other plant systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Coal Handling Plant And System Category

Industrial Material Handling Plant

Price 650000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : MS

Warranty : 1 year

Automatic Grade : Automatic

Voltage : 220 to 415 Volt (v)

100 Tons Capacity Coal Handling Plant

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : MS

Warranty : 1 year

Automatic Grade : SemiAutomatic

Voltage : 220 to 415 Volt (v)

Industrial Coal Handling Plant

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : MS

Warranty : 1 year

Automatic Grade : SemiAutomatic

Voltage : 220 to 415 Volt (v)

Fuel Handling System

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : MS

Warranty : 1 year

Automatic Grade : Automatic

Voltage : 220 to 415 Volt (v)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry